Aluminum-plastic board are very common in today’s industrial society. Many times we choose to use aluminum-plastic board with very good benefits. The reasonable use of the effects is very good. The society continues to develop and the types of products are increasing , aluminum-plastic board also have some similar products.

This time, the aluminum-plastic board manufacturer talked about the comparison between aluminum veneer and aluminum-plastic board processing.

At present, there are two kinds of aluminum veneer in the world: fluorocarbon sprayed aluminum veneer and roller coating, and a stick coating production line, so the processing of veneer here is mainly about fluorocarbon spray production.

There are two major steps in the production of sprayed aluminum veneer:

There are two major steps in the production of sprayed aluminum veneer:

The first step is sheet metal processing. This process is mainly through cutting, folding, arcing, welding, grinding and other processes on the flat plate to process the aluminum veneer into the shape and size required for construction.

The second step is spraying. Spraying is to spray paint on the processed sheet metal. There are two types of spraying, one is manual spraying and the other is machine spraying. Machine spraying is generally only suitable for regular flat plates, but this aluminum veneer is rarely used in actual use. Most manufacturers use manual spraying.

Manual spraying is a dangerous job, because the paint is relatively volatile and toxic, which can easily cause chronic benzene poisoning and seriously affect people’s health. A big advantage of manual spraying is that the color can be selected regardless of the amount, and the roller coating of aluminum-plastic board must reach a certain amount before it can be processed.

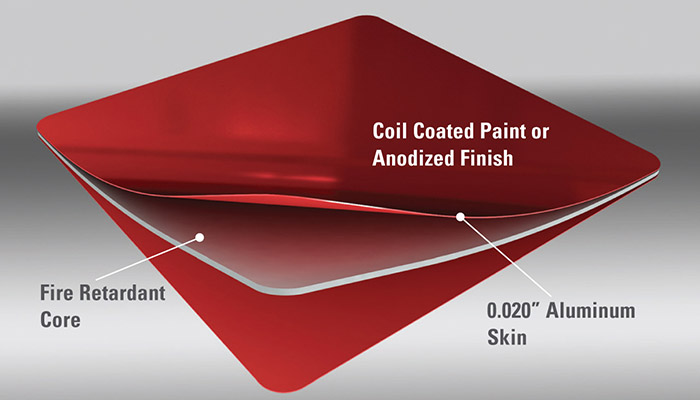

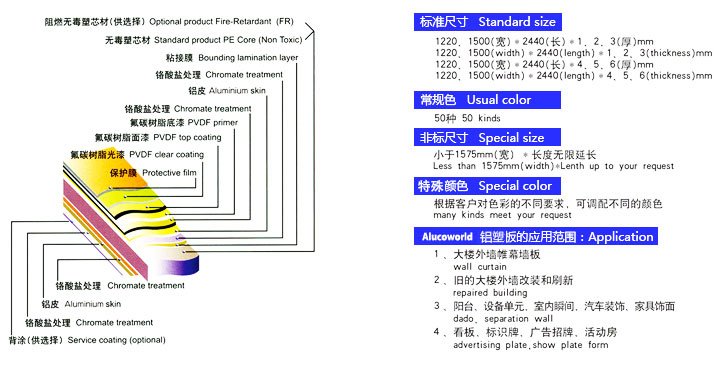

The processing of aluminum-plastic board is more complicated than that of aluminum veneer. There are four major processes: chemical conversion, painting, compounding and trimming. These four processes are automated production except trimming.

It can be seen from its processing process that aluminum-plastic panels have certain advantages in terms of environmental protection and safety. Coupled with the simple sheet metal adding process of aluminum veneer, some private workshops have also begun to get involved, which has seriously affected the stability of the market quality of aluminum veneer.

The above briefly describes the processing of aluminum veneer and aluminum plastic. Interested can learn more.

Relation articles:

7 powerful performances of acm cladding