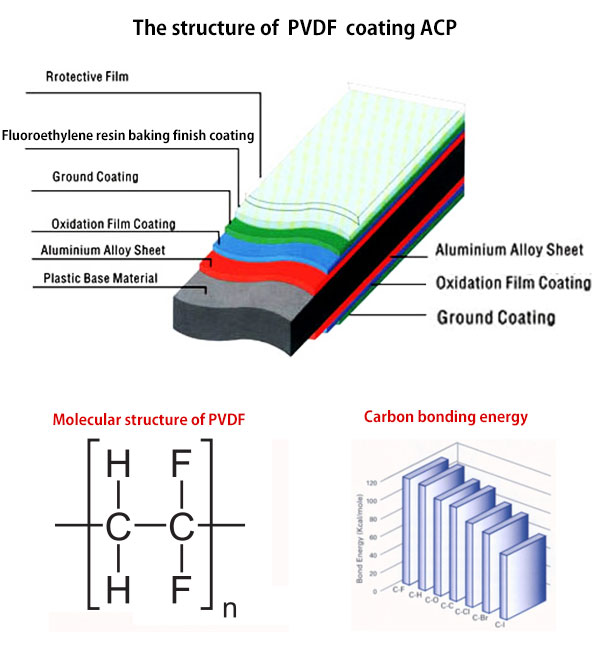

Polyvinylidene fluoride,whose abbreviation is PVDF, mainly refers to a vinylidene fluoride homopolymer, or a copolymer of vinylidene fluoride and other small amount of fluorine-containing vinyl monomer.

In the chemical structure, the fluorine-carbon bond is combined, and the structure with the short bond forms the most stable and strong bond with the hydrogen ion. Therefore, the fluorocarbon coating has specific physical and chemical properties, and not only has strong wear resistance and impact resistance,but also has high resistance to fading and UV lights in extremely harsh environments.

PVDF (polyvinylidene fluoride) has the strongest toughness, low friction coefficient, strong corrosion resistance, aging resistance, weather resistance and radiation resistance in fluoroplastics.

Pvdf coating characteristic:

Jiangsu kingertai new material technology co., ltd was established in 2003, we already have 17 years professional production and export eperience.

With strong strength, the company introduces Germany’s most advanced automatic hot-pressed composite aluminum-plastic panel production line and complete supporting testing equipment. Using high-quality materials such as the United States and Sweden, and using advanced Japanese aluminum-plastic production technology to produce every piece of panels.

The company has strong capital and advanced equipment. At the same time, we have a group of experienced professional management personnel and technical personnel.

Most important of all, putting our promise 100% into practice is always our principle. We do what we have promised, and try to be the best. We will always make you believe “One World, One Alucoworld”.

Due to its excellent properties, pvdf aluminum composite panels are generally used for exterior wall decoration, such as hospital, shopping mall, cinema, goverment, school, etc. What’s more, the thickness is preferably 4mm or more than 4mm.

For more products information, you are welcome to visit our website:https://www.alucoworldpanel.com/