1. What’s acm panel?

Acm panels is the abbreviation of aluminum composite material panels. It is a new type of building material composed of two different materials (metal and non-metal). Acm panel not only retains the main characteristics of the original constituent materials (metal aluminum, non-metal polyethylene plastic), but also overcomes the shortcomings of the original constituent materials, and thus obtains many excellent material properties, such as luxury, colorful decoration, weather resistance. Corrosion resistance, impact resistance, fire resistance, moisture resistance, sound insulation, heat insulation, shock resistance; light weight, easy processing, easy to handle and install, etc.

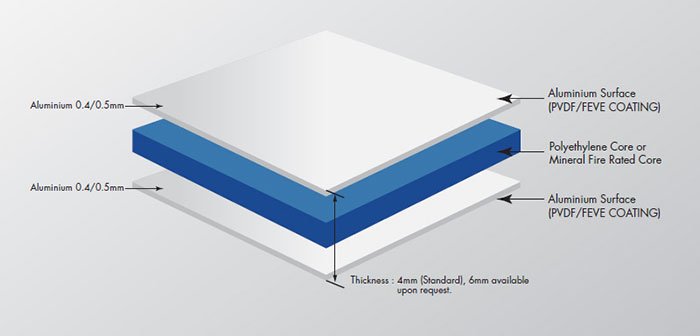

2.What’s composition of acm metal panel?

The acm panel is made up of multi-layer materials. The upper and lower layers are high-purity aluminum alloy plates with a non-toxic low-density polyethylene (PE) core plate in the middle, and a protective film is attached to the front surface. For outdoor use, the front side of the acm panel is coated with a fluorocarbon resin (PVDF) coating, and for the interior acm panel, the front side may be coated with a non-fluorocarbon resin.

3.What are the characteristics of acm panel?

(1)Super peeling degree

The acm panel adopts a new technology to improve the peeling strength to an excellent state, which is the most important technical index of the acm panels. In addition, the flatness and weather resistance of the acm paneling are correspondingly improved.

(2)Easy processing of acm metal panel

The acm paneling has a weight of only 3.5-5.5 kg per square meter, so it can reduce the damage caused by the earthquake and is easy to handle. The superior construction performance of acm paneling is reflected in the fact that acm panel can be cut, edge planing, bending into arc and right Angle of all kinds of shapes with only simple woodworking tools.

(3)Excellent fire performance

In the middle of the acm panel is a flame-retardant material PE plastic core material, and the two sides are extremely difficult to burn aluminum layer. Therefore, it is a safe fireproof material that meets the fire resistance requirements of building codes.

(4)Impact resistance

It has strong impact resistance, high toughness, no damage to the topcoat, strong impact resistance, and no damage caused by sandstorm in areas with large wind and sand.

(5)Super weather resistance

Due to the use of KYNAR-500-based PVDF fluorocarbon paint, weather resistance has a unique advantage, no matter in the hot sun or cold wind and snow, it does not detract from the beautiful appearance up to 15-20 years.

(6)Uniform coating

Through the chemical treatment and the application of Henkel's film technology, the adhesion between the paint and the acm panel is uniform and the color is diverse, allowing you to choose a larger space and show your individuality.

(7)Easy maintenance

The acm panel has been significantly improved in terms of pollution resistance. Nowadays in many countries, urban pollution is more serious. It needs to be maintained and cleaned after several years of use. Because of its self-cleaning properties, it only needs to use neutral detergent and water. After cleaning, the acm panels will be as new as ever.

(8)Easy processing

Acm panels are good materials that are easy to process and shape. It is an excellent product for efficiency and time. It can shorten the construction period and reduce costs. The acm paneling can be cut, cut, slotted, band sawed, drilled, machined, or cold-bent, cold-folded, cold-rolled, riveted, screwed or glued.

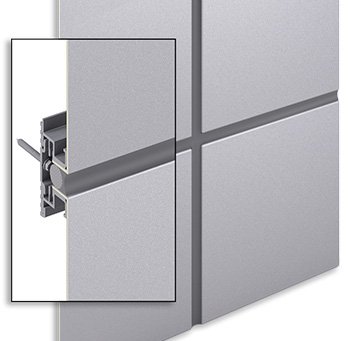

4.Learn about the attachment systems for acm panels.

(1) Wet seal system

Starting at the beginning of this evolution we’ll talk about the Route and Return Wet Seal System. This method (while not always the case) is typically considered to be the most economical way to install acm panel. It relies on a primary silicone sealant between each panel for an air and water barrier. The system utilizes basic male / female clips to attach the material to the building and can accommodate anything from the simple to the very complex panel designs.

(2)Dry seal system

As acm metal panel became a more popular façade solution, people started to identify some of the shortfalls of the Route and Return Wet Seal attachment method and began to develop systems to address these issues. The Route and Return Dry system functions similarly to the Wet Seal but gaskets are incorporated into the joints between panels in lieu of the silicone sealant. This allows the façade to stay much cleaner over time, in fact, rainfall typically is sufficient to keep the façade looking tidy.

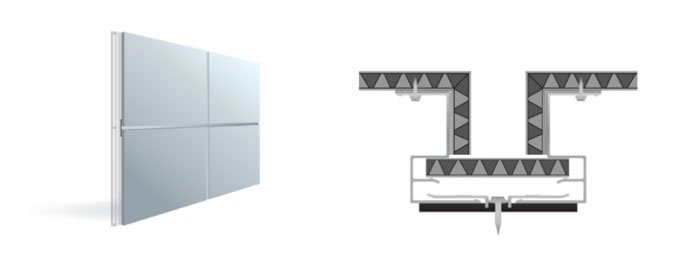

(3) Rain screen system

Today, variations of the Route and Return Rain Screen System are by far the most popular methods for installing acm metal panel. Reputable fabricators have subjected their rain screen solutions to rigorous air and water tests and an increasing number have also participated in fire testing. The fact that these contractors have taken it upon themselves to test their systems in accordance with strict building code requirements (and are willing to provide architects and designers with the results) has prevented many substandard fabricators from even participating in rain screen construction. Specifying a Route and Return Rain Screen increases the likelihood that the complete wall assembly, not only the acm metal paneling component, will function as designed and required by code. These highly engineered and tested systems have now addressed all of the deficiencies of the past.

5.why don‘t choose best acm panel?

Alucoworld is one of top 5 acm panel suppliers in China, ALUCOWORLD has been well adopted by customers from both at home and abroad.

We have built up great sales networks and service organizations in dozens of countries and regions around the world, such as Southeast Asia, the Middle East, North America, South America, Africa, Europe, etc.

We have agents in many countries, like Saudi Arabia, Sri Lanka, the Philippines, Libya, Mexico, Egypt, Tunis and so on. Meanwhile, we expect that more and more customers from different countries will pick ALUCOWORLD as the sole distributor.

In order to serve all of our customers better, we set up an international market department in Shanghai. Our specialized sales team can always offer the quickest response, best shipment and perfect after-sales service for all the customers.

Though there are a lot of acm panel suppliers in China, not all acm panel suppliers produce qualified products. If you want to buy the best acm metal paneling, alucoworld will be your best choice. Don’t hesitate to contact us now!

acm material

Upholding the principle of “Quality is the Life Core of an Enterprise”, Alucoworld acm material has also obtained various quality inspection certificates issued by authoritative quality inspection institutions at home and abroad, including: performance standards of ASTM aluminum-plastic composite panels by SGS international authoritative testing institutions, ROHS testing, etc.