1.The history of Alucobond panels

Alucobond Panels appeared in the 1960s. At that time, in order to meet the requirements of the transportation industry for ultra-lightweight materials, super-strength, and improve surface roughness, color uniformity, and molding properties,German technicians invented the aluminum-plastic composite panel by using the mechanics of the I-beam in steel. It began mass production in 1969.

After more than 30 years of development, product manufacturing, installation, maintenance, etc. have gradually matured, forming two major production processes: one is a cold composite process, and the other is a thermal composite process.

The hot composite process is high in peeling strength, and it is not easy to cause aluminum-plastic separation, it also has characteristics of flatness, long life and green environmental protection. Therefore, the hot composite process has become a more advanced technology and is the development trend of the aluminum plastic panel industry.

Up to now, Alucobond has developed from the first production base in Germany to the production bases in the United States, China,India, etc. This is also enough to prove that the aluminum plate conforms to the requirements of The Times, and occupies a pivotal position in the modern building materials.

Because of the first aluminum composite panel was named "Alucobond",in most countries, Alucobond also represents aluminum composite panel.

2.The introduction of alucobond manufacturter Alucoworld.

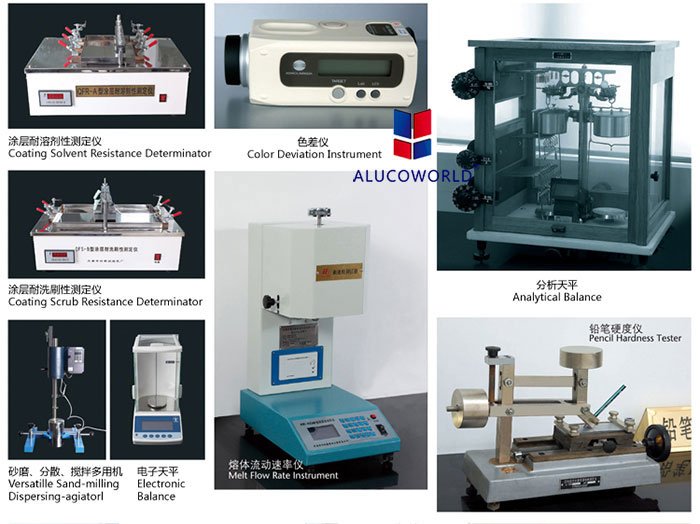

Taizhou Kingertai Decoration Material Co., Ltd. is a manufacturer specialized in alucobond panels in China. We are located in Taixing City, Jiangsu Province, 150km away from Shanghai. With over ten years' efforts, our company has gained great development in producing aluminum composite sheet.

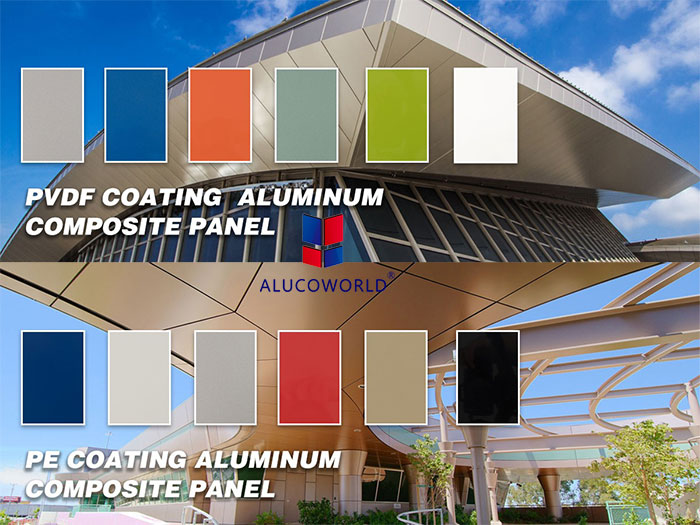

Kingertai has a complete strict quality assurance system, having passed ISO 9001 and ISO 2001 certifications successfully as well.

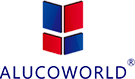

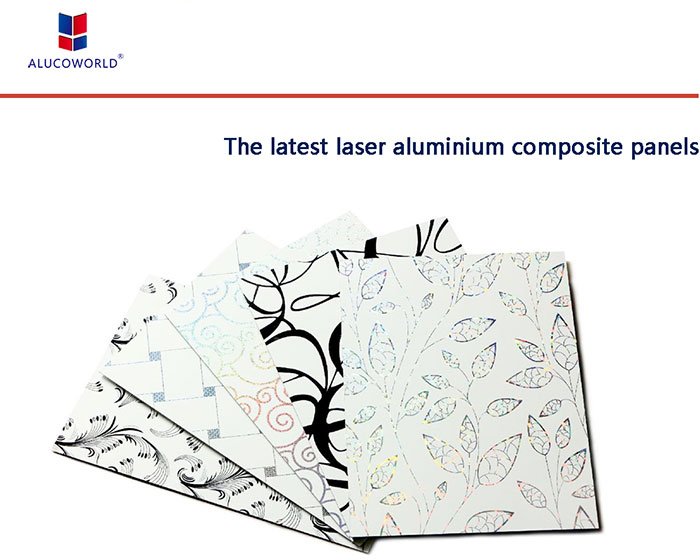

Kingertai’s main products include PE and PVDF coated aluminum composite panels, fire resistant, self-cleaning nano coated, mirror finish, brushed, wooden grain & granite grain aluminum composite panels and signboard aluminum composite panels for advertising usage, in addition, we are also able to produce 2m width aluminum composite.

Besides mainly producing ACP, we can also offer all accessories for ACP installation. Our annual output is more than 5 million square meters.

With the aim of building a beautiful and colorful world, ALUCOWORLD will always strive to make all of you satisfied, and will always make you believe "One World, One Alucoworld".

3.Features of Alucoworld alucobond panel

4.The thickness and size of alucobond panel

(1) Total thickness of alucobond panel

The total thickness of the aluminum-plastic panel is 2--6mm, and the thickness of the aluminum-plastic panel of the curtain wall is less than 4mm. Generally, the thickness of

(2) Alucobond panel sizes

The standard size is 1220*2440mm, width is 1000--2000mm, length is 1000--6000mm, and special specifications are negotiated.

5.Applicable scope of Alucoworld alucobond panels.

6. Project cases of Alucoworld alucobond panels.

Contact us

Every piece of alucoworld alucobond panel is strictly controlled in every process. We aim to produce all series of aluminum plastic panel with excellent performance for every customer.

We promise that your information will only be used for quotation, it will not be disclosed and is safe. Leave your message here or mail to [email protected], we will send the latest price list and arrange free sample for you !