Alucoworld is a Chinese company,with factory in Jiangxi province, and specialized in manufacturing brushed aluminum veneer. In order to make everyone know about the acm cladding better, today i will talk about the comparison of acm cladding material and aluminum veneer. acm panels

Metal sheet curtain wall applications have existed for decades, and metal sheet curtain wall is still in use, including aluminum veneers,acm cladding, and aluminum honeycomb panels. Among the three materials, the most commonly used are aluminum veneers and acm cladding. The earliest appearance of aluminum veneers, and later in the late 1960s and early 1970s, acm cladding were invented in Germany and quickly became popular around the world.

What is the difference between acm cladding and aluminum veneers? Here I will make a simple comparison of these two materials:

1. Material and cost of acm cladding and aluminium veneer

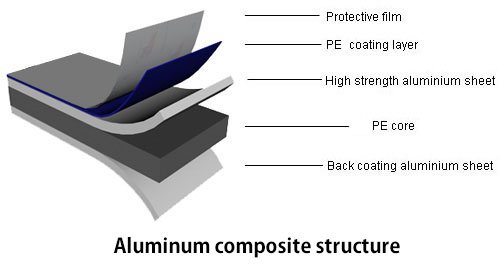

Aluminum veneer generally adopts AA1100 pure aluminum plate that the thickness is 2-4mm or AA3003 aluminum alloy plate. Generally, 2.5mm thick AA3003 aluminum alloy plate is used in China; aluminum-plastic composite board generally adopts 3-4mm three-layer structure, including upper aluminium layer and lower aluminium layer, whose thickness is 0 .5mm, the middle is PVC or PE. We can see from the material that the cost of aluminum-plastic composite panels is definitely much lower than that of aluminum veneers.

Aluminum veneer generally adopts AA1100 pure aluminum plate that the thickness is 2-4mm or AA3003 aluminum alloy plate. Generally, 2.5mm thick AA3003 aluminum alloy plate is used in China; aluminum-plastic composite board generally adopts 3-4mm three-layer structure, including upper aluminium layer and lower aluminium layer, whose thickness is 0 .5mm, the middle is PVC or PE. We can see from the material that the cost of aluminum-plastic composite panels is definitely much lower than that of aluminum veneers.

The current market is that the price of 4mm thick composite board is lower than the price of 2.5mm thick aluminum veneer close to 20 dollars per square, a 10,000 square project, the cost of aluminum composite panel will be lower than the cost of aluminum veneer close to 20 thousand dollars.

2.The processing of acm cladding and brushed aluminum veneer

At present, there are two kinds of aluminum veneers in the world, fluorocarbon sprayed aluminum veneers and roller coatings. There is no stick coating production line in China at present, so the processing process of veneers here is mainly about the production of fluorocarbon coating. Spraying aluminum sheets is divided into two major steps: the first step is metal sheet processing. This process is mainly to process the aluminum veneer into the shape and size required for construction by cutting, folding, bending, welding and grinding the flat plate.

The second step is spraying. Spraying is to spray paint on the processed sheet metal. There are two types of spraying, one is manual spraying and the other is machine spraying. Machine spraying is generally only suitable for regular flat plates, but this kind of aluminum veneer is used less in life, and manual spraying is adopted by most domestic manufacturers. Manual spraying is a dangerous job because the paint is highly volatile and toxic, and it is easy to cause chronic benzene series poisoning, which seriously affects people's health. One of the great advantages of manual spraying is that regardless of the amount, the color can be optional, and the roll coating of the aluminum-plastic panel must reach a certain amount before processing. The processing process of aluminum-plastic composite board is more complicated than that of aluminum single-board, mainly consisting of four processes of forming, painting, compounding and trimming. These four processes are automated except for trimming.

It can be seen from the processing process that the acm cladding has certain advantages in environmental protection and safety. Coupled with the simple process of sheet metal addition of aluminum veneers, some private workshops have begun to get involved, seriously affecting the stability of the market quality of aluminum veneers.

It can be seen from the processing process that the acm cladding has certain advantages in environmental protection and safety. Coupled with the simple process of sheet metal addition of aluminum veneers, some private workshops have begun to get involved, seriously affecting the stability of the market quality of aluminum veneers.

It can be seen from the processing time, acm cladding can be purchased on the market very easily. Irregular aluminum veneers require manual processing, so the waiting time is longer, which is not good for customers who are urgently used.

3.The product's appearance quality and physical properties

Appearance Quality of ACP Panels and Aluminum Veneers:

Aluminum veneer: The flatness of the flat plate is not high, and it looks like partial bump.

Acm cladding: flat plate flatness is relatively high.

The aluminum plastic panel can be processed into various irregular shapes; the quality of the spray roller coating is good, the color difference and the film thickness deviation are small.

Due to the instability of the artificial technology, the aluminum veneer has no local chromatic aberration, but the damage cannot be partially repaired.

Mechanical Property of Acm cladding and Aluminum Veneer:

The appearance of the aluminum veneer is worse than that of the aluminum plastic composite panel, but its mechanical properties are superior to those of the aluminum plastic composite panel, and its wind pressure resistance performance is superior to that of the aluminum composite panel. However, in most areas, the wind pressure value of aluminum plastic composite panels is completely affordable, so the use of aluminum veneers for engineering is really overkill.

4.The construction process

The construction process of acm cladding and aluminum veneers are the same in general.

The biggest difference is that the aluminum veneer is processed by the middleman or the manufacturer. Due to the accuracy of the domestic equipment, there are often some small troubles in the construction process, and the aluminum veneer is not suitable for processing on the spot, the aluminum veneer Can not be slotted, bent, because the bottom of the plastic bonding effect is not as good as the acm cladding.

On the contrary, the acm cladding can be processed into the required shape and specifications at the construction site, and has a large degree of construction freedom, which does not cause rework and increase the cost, consequently, it is favored by many customers. In addition to the guarantee of the delivery period of the construction process, the mass production of aluminum composite panels is much faster than the production of aluminum veneers.

5.Other aspects of comparison between acm cladding and aluminum single panel

(1)lightning protection characteristics

This problem has been debated for a long time, people think that the aluminum veneer is pure aluminum, and the conductivity is better. In response to this problem, Germany's ALUSUISSESINGEN GMBH made a lightning-proof test of two materials in a military laboratory in Munich, Germany. The results show that in the case of instantaneous impact during lightning strikes, the curtain wall connection method currently used can be completely protected against lightning strikes whether it is acm cladding or aluminum single panel.When the lightning strikes a continuous current, it is easy to melt at the lightning strike of the metal plate or the metal surface layer. Because of the good insulation of the intermediate polyethylene core layer of acm cladding, the damage of the lightning strike is limited to the skin. From this perspective, the acm cladding has better lightning strike resistance than the aluminum veneer.

This problem has been debated for a long time, people think that the aluminum veneer is pure aluminum, and the conductivity is better. In response to this problem, Germany's ALUSUISSESINGEN GMBH made a lightning-proof test of two materials in a military laboratory in Munich, Germany. The results show that in the case of instantaneous impact during lightning strikes, the curtain wall connection method currently used can be completely protected against lightning strikes whether it is acm cladding or aluminum single panel.When the lightning strikes a continuous current, it is easy to melt at the lightning strike of the metal plate or the metal surface layer. Because of the good insulation of the intermediate polyethylene core layer of acm cladding, the damage of the lightning strike is limited to the skin. From this perspective, the acm cladding has better lightning strike resistance than the aluminum veneer.

(2)Fireproof property

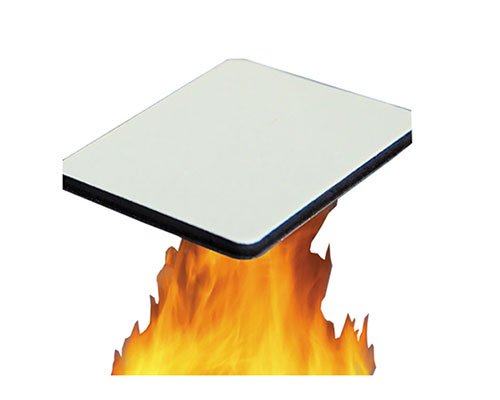

As everyone knows, aluminum veneers do not burn.

As everyone knows, aluminum veneers do not burn.

At the early stage, acm cladding were not fireproof. However, with the development of aluminum plastic plates technology, now acm cladding can fully meet the needs of engineering fire protection due to the addition of non-toxic and flame retardant materials in its PE.

(3)residual value

Aluminum veneers have a certain residual value, but because of their high cost, the waste is much larger than that of aluminum-plastic composite panels with almost no residual value.

Contact us

Every piece of alucoworld aluminum-plastic panel is strictly controlled in every process. We aim to produce the excellent aluminum-plastic panel with high peel strength for every customer.

Every piece of alucoworld aluminum-plastic panel is strictly controlled in every process. We aim to produce the excellent aluminum-plastic panel with high peel strength for every customer.

Want to buy excellent acp panels? Just mail to : [email protected] , we are waiting for you !

Aluminum Composite Panels Installation