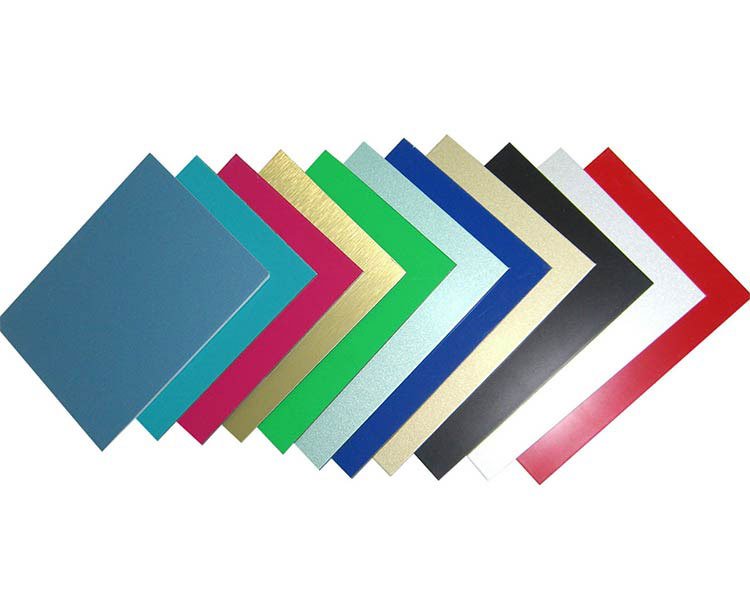

Do you know the difference between aluminum panels and aluminum composite panels? The aluminum sheet is a pure metal aluminum plate used for construction and decoration after chrome treatment and fluorocarbon spray technology. The aluminum-plastic composite board is a composite material. The chemically treated coated aluminum sheet is used as the surface material, and the polyethylene plastic is used as the core material, and processed by special aluminum composite board production equipment. So, what is the major difference between aluminum panels and aluminum composite panels? Shanghai ALUCOWORLD technicians will answer you:

a. Materials and prices

Aluminum plates generally use 2-4mm thick AA1100 pure aluminum plates or AA3003 aluminum alloy plates. Domestic manufacturers generally use 2.5mm thick AA3003 aluminum alloy plates; aluminum-plastic composite plates generally have 3-4mm three-layer structure, including upper and lower layers of 0.5mm. The aluminum coating sandwiches the plastic core. From the material we can see that the cost of aluminum composite panels is much lower than that of aluminum panels.

b. Process

At present, fluorocarbon sprayed aluminum sheets are mainly used for aluminum sheets produced in China. The machining process includes sheet metal part processing and spraying. Sheet metal processing processes the aluminum sheet into the desired shape and size by cutting, folding, bending, welding, polishing and other processes on the panel. Spraying is applied to the finished metal aluminum plate. One is manual spraying and the other is machine spraying. Machine spraying is usually only applicable to the rules of the flat plate, and one of the advantages of manual spraying is that the amount of size and color is optional.

Roll coating of aluminum composite panels must achieve a certain processing capacity. The processing of aluminum composite panels is more complicated than aluminum panels because it has four processes: forming, coating, compounding and trimming. In addition to repairing edges, these 4 processes can be generated automatically. Therefore, it can be seen from the processing that the aluminum composite panel has certain advantages in terms of environmental protection and safety. In addition, in addition to professional manufacturers of aluminum sheets, there are also some private workshops that have begun to set foot in the production of aluminum sheets. These unprofessional products have seriously affected the stability of the quality of the aluminum sheet market.

Roll coating of aluminum composite panels must achieve a certain processing capacity. The processing of aluminum composite panels is more complicated than aluminum panels because it has four processes: forming, coating, compounding and trimming. In addition to repairing edges, these 4 processes can be generated automatically. Therefore, it can be seen from the processing that the aluminum composite panel has certain advantages in terms of environmental protection and safety. In addition, in addition to professional manufacturers of aluminum sheets, there are also some private workshops that have begun to set foot in the production of aluminum sheets. These unprofessional products have seriously affected the stability of the quality of the aluminum sheet market.

c. Performance and cost:

The appearance of the aluminum plate is inferior to that of the aluminum composite plate, but its mechanical properties are superior to those of the aluminum composite plate, and its wind pressure resistance is superior to that of the aluminum composite plate. However, fire resistant aluminum panels are non-combustible materials. Early aluminum-plastic composite panels could not be fireproof, but with the development of aluminum composite panel technology, the fire resistance of fire-resistant aluminum-plastic composite panels has been greatly improved due to the addition of non-toxic flame retardant materials to PE. It has been able to fully meet the needs of engineering fire protection. The residual value of the aluminum plate has a certain residual value, but because of its high cost, the waste caused by the aluminum-plastic composite board has almost no residual value.

The above three points are the main difference between aluminum panels and aluminum composite panels. If you are still hesitant to buy what aluminum wall panel is used as building materials, then I think this article will help you. If you want to buy a strong aluminum composite board, then choose our ALUCOWORLD will be your best choice.

acm material

https://www.alucoworldpanel.com/why-choose-alucoworld-acp-panels/

Upholding the principle of “Quality is the Life Core of an Enterprise”, Alucoworld acm material has also obtained various quality inspection certificates issued by authoritative quality inspection institutions at home and abroad, including: performance standards of ASTM aluminum-plastic composite panels by SGS international authoritative testing institutions, ROHS testing, etc.